ESG and Sustainability

As part of our ongoing commitment to CSR, we have made an ESG report, even though we, as an SME, are not legally required to do so under EU legislation. As a responsible Danish manufacturer and workplace, we have prepared the ESG report to meet the increasing demands for transparency and responsible practices from our stakeholders.

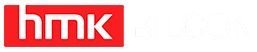

Therefore, through a longer project process with the consultancy firm Viegand Maagøe A/S, we have worked to get an overview of the material and financial impacts on our business. In the project, we have conducted a double materiality analysis to map our value chain, identify ESG topics, involve stakeholders, and prepare an IRO assessment.

Climate Compass

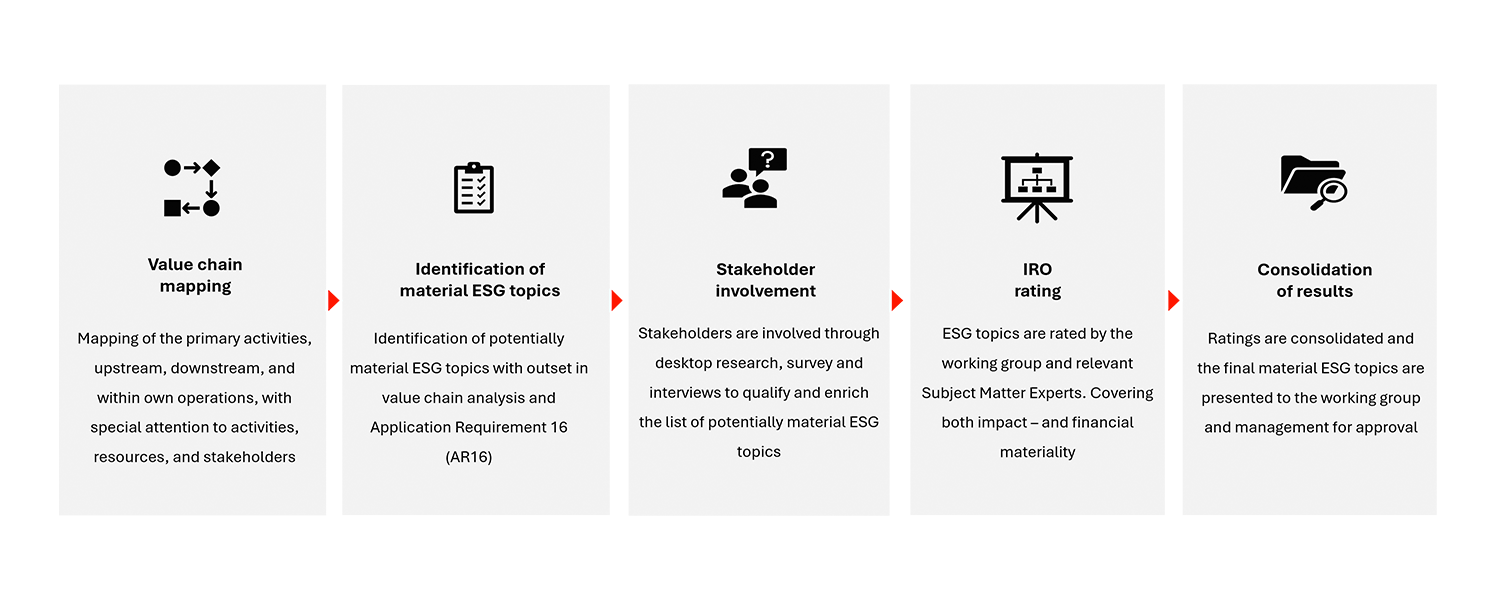

In the project, we have also worked with the Danish Business Authority’s Climate Compass to get an overview of our CO2 emissions and thus uncover our Scope 1, 2, and 3. We have prepared climate accounts for 2021, 2022, 2023, and 2024, and so far, we have adopted a cradle-to-gate approach, as we currently do not have information about our products after delivery to customers.

Regarding Scope 3, the figures are based on estimates, as we do not have exact figures for the impacts related to the purchase of components, which account for the largest share of our CO2 emissions.

ESG Report

We have compiled the results from our ESG project in a report. In the report, we delve deeper into the various ESG topics, the Climate Compass and CO2 emissions, our ISO certifications, and the improvements we have made over the years to optimize our energy consumption.

Now that we have gained a better understanding of our CO2 emissions, we will start working on setting goals for reducing emissions. We will look more closely at what we can influence ourselves and where we can place demands on our suppliers for new reduction measures.

Quality, environment, cybersecurity, and certifications

ISO 9001 and 3834-2

We produce products of the highest quality with great durability and the industry’s longest lifespan.

Therefore, we have chosen to work systematically with the ISO 9001 quality management system, which we are certified in. In addition, we have a number of welding certifications such as ISO 9606-2 for the construction of tanks according to EN 13094:2020+A1:2022 as required by ADR 2025, ISO 10042:2018 for welding and arc welding of joints in aluminum and its alloys, and DS/EN ISO 13445-4:202021+A1:2023 for the design and manufacture of pressure vessels.

Furthermore, we are ISO certified according to the welding standard ISO 3834-2:2021 to meet quality requirements for fusion welding of metallic materials.

ISO 14001

We were ISO 14001:2015 certified in 2020, which means that we work systematically to minimize our environmental impacts in daily operations. In the management system, we have, among other things, developed an environmental policy and set goals for improvements.

DIN 2303 Q2BK2

In 2022, we were DIN 2303 Q2BK2 certified. The certification means that we are now approved to weld in all types of steel (except reinforced steel) according to the German welding standards.

ISO 27001

Due to the increasing threat level against IT systems and infrastructure in general, we were ISO 27001:2022 certified in December 2024. It is a management system for cyber and information security, which is also closely aligned with the EU’s NIS2 directive.

We have significantly raised our security level and will continue to allocate resources to combat the ever-increasing cyber threats.

Digitalization

We have implemented several digitalization projects that streamline a number of internal work processes in the company. There are many projects to tackle, and we are not yet finished. So far, it has meant that we have:

- Implemented tablets in production and reduced paper consumption in our work processes

- Created digital project management

- Increased productivity in our production through the use of digital technical documentation

- Reduced delays in production by implementing an electronic warehouse scanning system with barcodes

- Reduced unnecessary driving for urgent orders

- Implemented two welding robots

- Started implementing a new IT system for management reporting, quality management, and production optimization

UN´s 17 Sustainable Development Goals

We have worked with the UN’s Sustainable Development Goals and selected six goals that make sense for us in terms of where we can contribute and make a difference.

- We work closely with educational institutions to help students and apprentices develop their professional skills

- We have always employed apprentices within relevant fields

- We have employees in senior jobs, flex jobs and wage subsidies

- All employees are offered further training in, among other things, LEAN.

- We reuse water for pressure testing of tanks

- We have water-saving taps in toilets and bathrooms

- Washing areas are connected to wells with oil separators

- We are continuously working to optimize energy throughout the company

- We purchase green electricity wherever possible

- We are working to integrate solar cells into our products

- We use LEAN management to increase production efficiency

- We will streamline the use of resources and increase the use of clean and environmentally friendly technologies and industrial processes

- We handle chemicals and waste in an environmentally sound manner

- Waste volume must be significantly reduced through prevention, reduction, recycling and reuse

- Integrating sustainability information into our reporting cycle

- Almost all computers, servers and phones are purchased refurbished/recycled

- We are an active member of the Network for Sustainable Business Development North Denmark and participate in sustainable development projects, including The Green Travel Team

- We work closely with Business Aalborg on various development projects

- We have done green screening and green strategy together with House of Energy

- We are a member of the Aalborg Alliance and the Climate Alliance

- We collaborate with High:five to help young people on the edge back into the labor market

- We are a member of Interforce, which supports Denmark’s defense and preparedness with employees who are part of the reserve force

Improvements

In recent years, we have made a number of improvements in the company that all contribute to reducing our energy consumption and improving working conditions. We are far from finished, but we are continuously working on improvements that have a positive effect.

Improvement projects 2025/2026

In 2025, we will continue to make improvements in the company in various areas:

- Expansion of the service workshop

- Re-establishment and optimization of the washing hall

- Purchase of more welding manipulators

- Establishment of more noise barriers

- Additional room extraction in the painting department

- Renovation of changing facilities in the test and painting department

- Purchase of electric forklift

- Central system for welding gas established

- Purchase of green electricity certificates

Completed Improvements 2018-2024

- 100% of our electricity came from renewable energy sources such as hydropower and wind energy in Denmark and Norway (2021-2022)

- Investment in a new painting cabin with an industrial gas system (LPG), which has reduced CO2 emissions by 27% and S2 by 99%

- LED lighting established in production halls and office building

- New frequency-controlled compressor established, which reduces electricity consumption

- Optimization of district heating consumption through district heating control

- Calorifiers have been cleaned and replaced with newer, more efficient models

- 8 smaller heat pumps have been installed to supplement heating

- Electric water heaters have been installed instead of oil water heaters in the assembly hall

- Water-saving taps have been installed in bathrooms and toilets.

- 2 new low-pressure ventilation systems with heat recovery and frequency control have been installed

- All point extraction systems have been sealed

- All doors have been sealed

- Roof insulated over all painting cabins

- Reduced paint consumption by switching to better products

- Purchase of new welding machines that use less electricity

- Establishment of waste sorting for recycling, including steel, stainless steel, aluminum, and combustible material

- Cardboard and paper are recycled for shipments

- We only use carriers that at least meet the EU5 standard

- All vehicles have been replaced with new models that drive twice as far on the liter, which applies to both forklifts and company cars.

- New electric forklifts, pallet trucks, sweepers, tractor, and a tug have been purchased, which are less burdensome

- Floors painted light to improve the working environment

- New noise-reducing sound walls in troldtekt set up in the tank area

- Recycling of water during pressure testing

- District heating established for heating the test and painting hall instead of oil heating

- Sealing of compressed air systems

- Purchase and commissioning of a smaller welding robot

- Replacement of windows in the administration building and insulation of masonry

- Establishment of more drains to accommodate larger amounts of rain

- Setting up a new fence all the way around the property

- Upgrading of the cold hall

- Purchase and commissioning of a large welding robot

- Purchase of more welding manipulators

- Renovation of warehouse offices

Working Conditions and Work Environment

For us, working conditions and the work environment are crucial factors for running a healthy business. Therefore, we place great emphasis on ensuring good and safe physical and psychological working conditions for our employees. We, of course, follow all applicable regulations in the area and prepare workplace assessments to continuously improve the working environment.

We demonstrate social responsibility in all employment relationships and employ skilled labor and have employees in flex jobs, senior jobs, and wage subsidies. Our staff is professionally organized, and we have a much higher proportion of apprentices employed than required by law. We are members of the Confederation of Danish Industry and follow the Industrial Agreement, which ensures that all employees have orderly conditions and terms.

For us as a company to move forward, it is important to have new input and ideas. Therefore, we often collaborate with students from Aalborg University and UCN on development projects within energy optimization, sales and marketing, production optimization, HR, and management. In addition, we have carried out a major well-being project for all employees with a focus on diet, smoking, alcohol, exercise, and stress.